Power Supply and Control System Mismatches Causing Crane Delays

Power Supply and Control System Mismatches: A Common Cause of Delays

Most Important Takeaway

Mismatched power supply and control systems are one of the top reasons overhead crane projects face post-delivery delays, increased costs, and operational risks. Ensuring compatibility at the planning stage prevents installation setbacks and long-term maintenance headaches.

Key Takeaways

- Understanding voltage, phase, and frequency requirements prevents system incompatibility.

- Control system design must match crane type and operational needs to avoid downtime.

- Early verification of power supply and control system compatibility reduces installation delays.

- Misalignment between electrical infrastructure and crane specifications can cause costly modifications.

- Integrating safety features and automation depends on compatible control systems.

Introduction

When it comes to overhead cranes, the devil is often in the details—especially in the electrical system. Power supply and control system compatibility might sound technical, but in practice, it’s one of the most common reasons crane projects face delays after delivery. A mismatch between the crane’s electrical needs and the site’s power infrastructure can halt installation, increase costs, and sometimes even damage equipment.

Many projects underestimate this early in planning. You might have a perfectly designed crane, but if the local power supply doesn’t match or the control system isn’t compatible, the crane can sit idle for weeks while engineers troubleshoot. It’s not just an inconvenience—it can delay production schedules, affect operational safety, and add unexpected costs to your project.

This guide is written for the people who make these decisions every day: procurement engineers, project managers, and technical buyers responsible for selecting and installing overhead cranes. By understanding the practical aspects of power supply and control system compatibility, you can prevent common installation delays and ensure the crane performs reliably from day one.

Key points to understand in this guide:

- Why voltage, phase, and frequency must match the crane’s design.

- How control system mismatches impact safety and operation.

- Practical steps to verify electrical and control compatibility before installation.

- How early planning can reduce downtime and retrofit costs.

Power Supply Requirements

Power supply is not just a number on a datasheet—it's the foundation for the crane's performance. Getting it wrong can lead to serious problems, from slow commissioning to costly repairs. Understanding voltage, phase, frequency, and power quality is essential before you even order the crane.

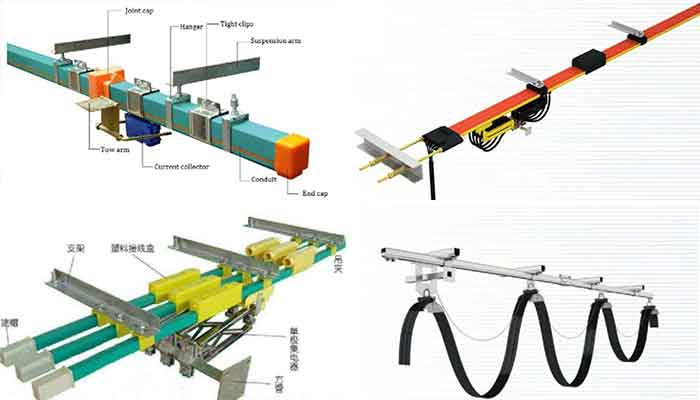

4 Types of Crane Power Supply Lines for Overhead Cranes, tailored crane supply systems for your needs

Voltage, Phase, and Frequency Compatibility

Overhead cranes require the right combination of voltage, phase, and frequency to operate safely and efficiently. Even small differences can lead to unexpected downtime.

Single-phase vs. Three-phase systems

- Single-phase power is usually limited to smaller, light-duty cranes.

- Most industrial overhead cranes, including EOT cranes and double-girder designs, require three-phase power to run motors efficiently.

Regional standards

- North America typically uses 480V three-phase power for industrial cranes.

- Europe commonly uses 400V three-phase systems.

- Asia and other regions may have 380V, 415V, or other standards.

- Always confirm the local electrical standard before finalizing crane specifications.

Practical tip: A 20-ton double girder crane designed for European voltage cannot be directly connected to a US 480V supply without proper transformers or motor adjustments. Overlooking this early can stall the project for days or weeks.

Impact of Incorrect Voltage or Phase

Using the wrong voltage or phase setup can create problems that aren't obvious at first.

Motor underperformance or failure

- Motors may overheat or fail to start if the voltage or phase doesn't match the crane's requirements.

- This can reduce lifting capacity, slow operations, or trigger emergency stops.

Risk of electrical component damage

- Variable frequency drives (VFDs), contactors, and control relays can be damaged by inconsistent power.

- Replacing components after delivery often costs more than the initial planning effort.

Practical tip: Always ask the crane supplier for the exact motor and drive specifications and check that your site can meet them. Small mismatches can escalate quickly once the crane is installed.

Power Quality Considerations

Even if voltage and phase match, the quality of the power can affect crane performance. Poor power quality can be invisible until the crane is running.

- Harmonics: Distorted current can cause motors and drives to overheat.

- Voltage fluctuations: Drops or spikes can trigger control system errors or stop the crane unexpectedly.

- Short-circuit capacity: The site's power system must handle the crane's startup currents safely.

Effects on sensitive control electronics:

- PLCs, remote controls, and automated systems can behave unpredictably under unstable power.

- Safety circuits may fail, increasing risk to operators and equipment.

Practical tip: Consider installing surge protection, voltage stabilizers, or harmonic filters if your facility experiences inconsistent power. This prevents damage and avoids delays during commissioning.

Control System Mismatches

Even with the right power supply, a crane can underperform or cause delays if the control system isn’t properly matched. Control systems connect the operator to the crane’s mechanisms, and a mismatch can affect efficiency, safety, and reliability. Understanding the types of control systems and potential pitfalls helps avoid installation headaches.

Crane Control: Remote control, Pendant Control & Cabin Control and crane automation

Types of Crane Control SystemsCrane control systems come in different forms, and each has practical considerations:

- Push-button pendant – Common for most standard overhead cranes. Requires matching control voltage and wiring. Small mistakes can prevent motors from running correctly.

- Radio remote control – Offers mobility and flexibility, but requires proper frequency and signal setup to prevent interference with other equipment.

- Cabin control – Typically used for large, high-capacity cranes. Needs integration with site automation and careful configuration of communication protocols.

- PLC-based automation or semi-automatic systems – Used in precise or repetitive operations. Must align with crane motors, drives, and safety systems. Even small timing or logic errors can cause functional issues.

Tip: Always confirm your site’s existing electrical and control systems before choosing a control method. This prevents surprises when the crane arrives.

Common Mismatch Scenarios

Control mismatches usually appear during installation or testing. Some frequent issues include:

- Control voltage not matching crane components – can stop motors or damage relays.

- Conflicting communication protocols – e.g., a crane using Modbus can fail to communicate with plant PLCs using Profibus.

- Safety interlock inconsistencies – emergency stops or limit switches may not operate correctly if the control system is not compatible.

Practical tip: Ask your supplier for wiring diagrams, control schematics, and software settings before the crane ships. Even a quick review can prevent weeks of troubleshooting.

How Mismatches Affect Operations

The consequences of a control mismatch are immediate and tangible:

- Delayed or inconsistent crane response – Motors may lag or fail to respond to commands, reducing productivity.

- Safety risks – Faulty emergency stops or malfunctioning interlocks can create hazards for operators and equipment.

- Compliance issues – Non-aligned control systems may fail to meet local safety regulations, risking fines or operational shutdowns.

Practical tip: If possible, run a staged pre-commissioning test at the supplier’s site or a controlled environment. It allows you to catch issues early before the crane goes live.

In short, control system mismatches are often invisible until the crane is operating. Early verification, compatibility checks, and pre-testing are the best ways to avoid delays, ensure safety, and keep production running smoothly.

Causes of Delays from Mismatches

Control and power system mismatches often don’t show up until the crane is on-site. By then, the clock is ticking, and small problems can quickly turn into weeks of delays. Understanding the main causes helps project teams prevent surprises and keep schedules on track.

Late Discovery During Installation

One of the most common reasons for delays is discovering the mismatch too late. Often, the crane arrives, and the team realizes:

- Voltage or phase doesn’t match the site supply.

- Control system signals fail to communicate with existing PLCs.

- Emergency stops or limit switches don’t respond as expected.

By this point, electricians and technicians must troubleshoot on-site, which can take days or even weeks.

Tip: Check power supply and control system compatibility during planning, not just at installation. Early verification saves time and frustration.

Additional Retrofitting Costs

When mismatches are found on-site, retrofitting is almost always required. This could include:

- Installing voltage converters or transformers.

- Rewiring control circuits to match local standards.

- Upgrading PLCs or software to match crane automation systems.

These fixes are not only costly, but they can also delay the start of operations, sometimes significantly.

Extended Commissioning and Production Downtime

Even minor mismatches can extend the commissioning period. Testing, troubleshooting, and correcting errors takes time. In some cases:

- Production lines remain idle while the crane is adjusted.

- Operators and maintenance teams must be retrained for new settings.

- Safety checks must be repeated to ensure compliance.

The result is lost productivity and delayed project timelines.

Coordination Challenges Between Supplier and Local Team

Fixing mismatches often requires multiple parties to work together:

- Crane supplier engineers may need to remotely guide installation adjustments.

- Local electricians must interpret crane documentation and modify wiring or software.

- Miscommunication can lead to repeated errors and further delays.

Practical tip: Establish clear communication channels with your crane supplier early, including documentation for control systems and electrical requirements. This reduces misunderstandings and speeds up problem-solving on-site.

Best Practices to Prevent Mismatches

Preventing power supply and control system mismatches starts long before the crane arrives on-site. A little preparation upfront can save days or even weeks of troubleshooting and reduce unnecessary costs. Here's how to do it in practice.

Early Planning

The first step is gathering accurate information about your site's electrical infrastructure. Don't guess—measure and document everything.

- Gather site electrical data: Confirm voltage, phase, frequency, and load capacity. Check for any unusual characteristics like voltage fluctuations or harmonic distortions.

- Confirm regional standards: Make sure your facility meets local electrical regulations. For example, North America typically uses 480V 3-phase power, while Europe commonly uses 400V 3-phase.

Practical tip: Document all electrical data and share it with your supplier before finalizing the crane order. Early planning prevents last-minute surprises that could halt installation.

Supplier Verification

Your crane supplier should be your partner in preventing mismatches. Clear communication at this stage avoids retrofits later.

- Provide detailed crane specifications: Include lifting capacity, motor type, drive system, and control system requirements.

- Confirm control system compatibility: Check that the control voltage, communication protocols, and automation features match your site infrastructure.

Practical tip: Ask your supplier for wiring diagrams, control schematics, and recommended installation practices. A simple review can prevent errors and save weeks of downtime.

Testing Before Installation

Verifying everything before installation is critical. Even the best planning can't replace real-world testing.

- Pre-commissioning checks at the factory: If possible, test the crane with its control system and power supply setup at the supplier's facility. This allows problems to be fixed before shipping.

- On-site testing of power and control: Once installed, test the crane under real conditions before putting it into production. Check motors, drives, safety circuits, and automated functions.

Practical tip: Treat pre-commissioning and on-site testing as part of your schedule—not optional extras. Early testing identifies hidden issues and ensures a smooth start-up.

Practical Tips for Buyers

When buying an overhead crane, it's easy to focus on lifting capacity or brand reputation and overlook the small but critical details that affect installation. Power supply and control system compatibility is one of those details. Following a few practical steps can save time, money, and frustration.

Include Compatibility Checks in RFQs and Tenders

Before inviting quotes or bids, make sure your requests clearly specify the electrical and control requirements.

- Ask suppliers to confirm voltage, phase, and frequency compatibility.

- Request details on the control system type, communication protocols, and safety interlocks.

- Highlight any special requirements, like remote operation or semi-automatic functions.

Practical tip: Explicitly including these checks in RFQs avoids back-and-forth clarifications and reduces the chance of ordering an incompatible crane.

Request Documentation

Documentation is your best defense against surprises.

- Ask for wiring diagrams, control schematics, and motor specifications.

- Request guidance on site preparation, such as recommended grounding, power supply, and cable sizing.

Practical tip: Reviewing documentation before the crane arrives helps your local team identify potential issues early and ensures the site is ready for installation.

Consider Future Expansion and Automation Needs

Think beyond today's operations. Your facility might upgrade or expand, and your crane should be ready for it.

- Plan for additional automation, like semi-automatic lifts or PLC integration.

- Verify that control systems and power supply can support future upgrades without major retrofits.

Practical tip: Choosing a slightly more flexible control system upfront can save significant costs if operational requirements change later.

Maintain a Site Readiness Checklist

Having a checklist ensures nothing is overlooked.

- Include electrical supply verification, control system compatibility, and physical site preparation.

- Confirm load capacity, cable routing, grounding, and space for maintenance access.

- Include pre-commissioning tests and safety checks.

Practical tip: A simple checklist can prevent last-minute surprises, speed up installation, and ensure the crane operates safely and reliably from day one.

By taking these practical steps, buyers can prevent delays, reduce retrofit costs, and avoid safety risks. The goal is simple: get the crane installed and operational on schedule, with minimal stress and maximum reliability.

Questions This Guide Solves

This guide is designed to address the real challenges buyers face when selecting and installing overhead cranes. Here's how it answers the most common questions:

How do power supply specifications affect crane installation?

Power supply specifications—voltage, phase, and frequency—directly determine whether a crane will operate safely and efficiently. If these do not match the crane's design:

- Motors may underperform or fail to start.

- Electrical components, including drives and relays, can be damaged.

- Commissioning is delayed, sometimes for days or weeks, while on-site adjustments are made.

Practical takeaway: Accurate site measurements and early verification with the supplier prevent costly surprises during installation.

What are the common control system mismatches in overhead cranes?

Control system mismatches can appear in several ways:

- Incompatible control voltage with crane components.

- Conflicting communication protocols (e.g., Modbus vs. Profibus).

- Misaligned safety interlocks or emergency stop systems.

Practical takeaway: Confirm the crane's control system type, wiring diagrams, and software configuration with the supplier before delivery.

How can buyers verify compatibility before purchase?

Buyers can take proactive steps to ensure everything will work together:

- Include power and control checks in RFQs or tender documents.

- Request detailed electrical and control system documentation.

- Conduct pre-commissioning tests at the supplier's factory, if possible.

Practical takeaway: Early verification reduces retrofits, delays, and unexpected costs.

What operational risks arise from electrical mismatches?

Electrical mismatches can cause both efficiency and safety issues:

- Delayed or inconsistent crane response affects production workflow.

- Faulty emergency stops or interlocks increase the risk of accidents.

- Non-compliance with safety regulations can result in fines or operational shutdowns.

Practical takeaway: Ensuring compatibility protects both operators and equipment while keeping production running smoothly.

How to prevent post-installation delays caused by electrical issues?

Preventive measures are always cheaper than corrective action:

- Gather complete site electrical data and verify regional standards.

- Confirm supplier compatibility for both power supply and control systems.

- Test the crane under real conditions before full commissioning.

- Maintain a site readiness checklist covering power, control, and safety systems.

Practical takeaway: Planning, testing, and documentation are key to avoiding costly post-installation delays.

Conclusion

Power supply and control system mismatches are some of the most common—but also most preventable—causes of delays in overhead crane installation. Even a well-designed crane can remain idle for days or weeks if electrical requirements and control compatibility aren’t verified before delivery.

The solution lies in proactive planning. Start by collecting accurate site electrical data, confirming regional standards, and sharing detailed crane specifications with your supplier. Combine this with thorough verification, including wiring diagrams, control schematics, and pre-commissioning tests, to identify potential issues early. Close collaboration between your supplier and local technical teams ensures problems are resolved before they affect production.

Aligning the power supply and control systems during the planning stage ensures your overhead crane operates smoothly from day one. This approach minimizes downtime, prevents unexpected costs, and protects your investment—keeping your operations on schedule and your team safe.